The choice of the paint depends on your environment and the application of the steel material. The common paints used include oil based, high-build epoxy products and vinyl/vinyl copolymer systems.

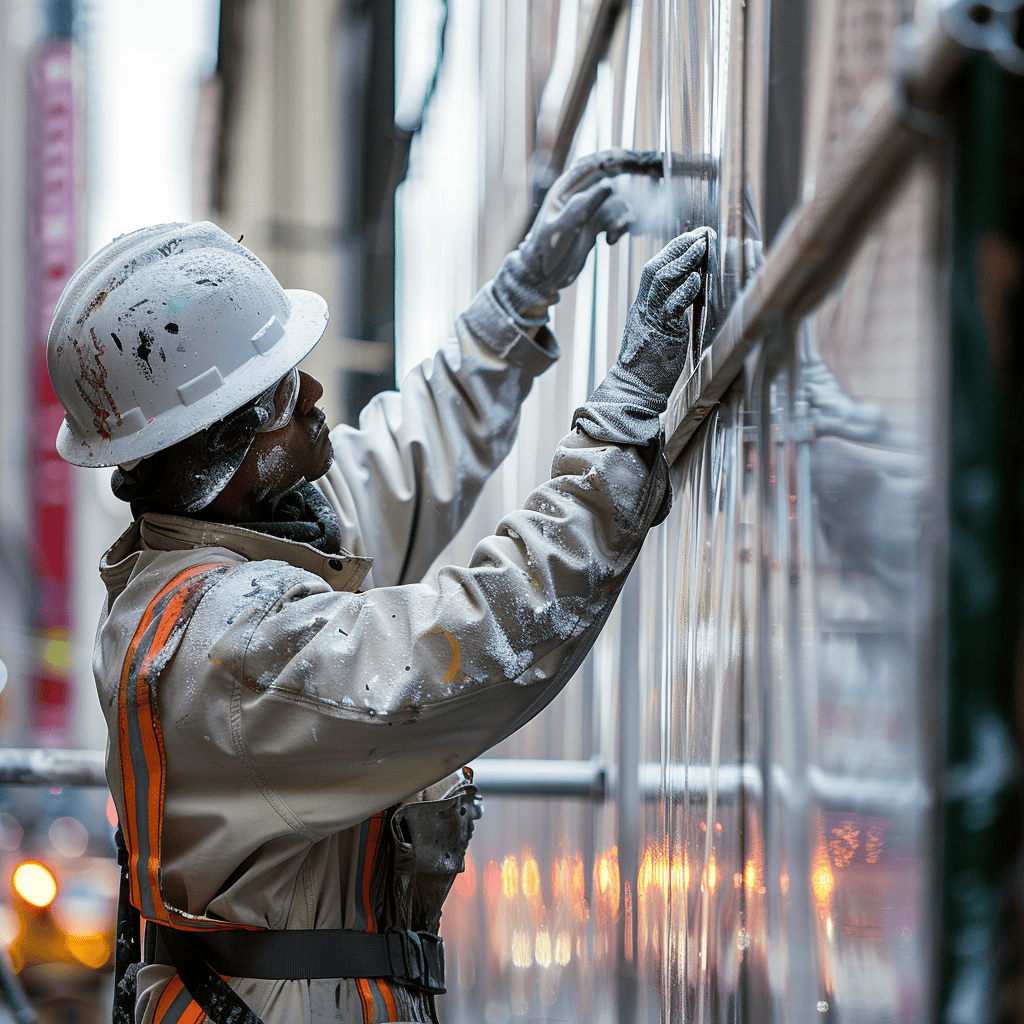

Painting is an effective method for preventing corrosion on steel surfaces and ensuring durability. When painting steel, surface preparation is one of the most important steps. If the steel has already rust on it, the steel needs to be cleaned with abrasive or hydro blasting. After that, the rust needs to be removed using an angle grinder. Rust inhibitor, arrester, or converter is used next followed by industrial finish coats.

The pretreatment of the galvanized components is best done after the steel has been galvanized. Some of the methods that you can use in surface pretreatment include:

T-wash: T-wash is a modified zinc phosphate solution with a little copper salt. It is left to dry and react with the steel surface before the excess is removed by water.

Etch primers: Etch primers work like T-wash but there is no visible change in color.

Sweep blasting: This method cleans the film off the surface allowing the paint to bond to the steel.

To ensure that the paint protects the steel surface as much as possible, consider the following factors.

The environment: Consider the humidity, temperature, exposure to chemicals and the presence of UV radiation.

Type of surface: Each material such as stainless steel or galvanized steel has a different way of coating. Check the surface properties before selecting a coat.

The durability of the paint system: The lifetime of any coat is determined by the period it takes before the first maintenance after the fresh paint application. The durability of the paint is affected by the pretreatment grade before the painting.

Discover the difference that attention to detail and personalized service can make. Choose us for a transformation that speaks volumes.

Your peace of mind is paramount. As a fully licensed and insured company, we uphold the highest standards of safety and compliance. You can rest easy knowing your project is in the hands of credible professionals.

Do you have an amazing idea that we could build together?